For the first 57 years of its existence, Fairbank Oil Fields relied on the power of steam, horses and the physical strength of the oil men.

When John Henry Fairbank arrived in Oil Springs in 1861, individual portable steam engines were sometimes used to pump each well. This was expensive and extremely awkward. The land was only roughly cleared and many wells were in swampy woods.

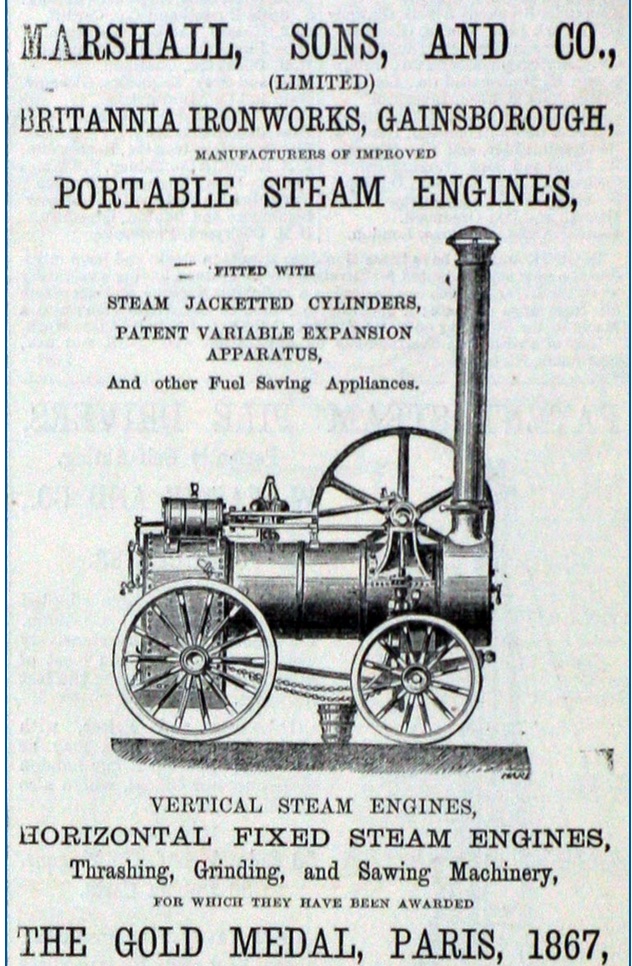

During the 1860s, oil men would have used a portable steam engine like this one to power their wells.

Even so, the steam engines could do what sheer strength of a man could not. Before steam engines were introduced, the majority of wells were pumped by man power with a spring pole. Physically, this was exhausting and had its limits.

In 1863, Fairbank devised the jerker-rod system, linking several wells to one portable steam engine to power the pump. As he later explained to the Ontario Royal Commission of 1890, “I remember the time the first jerker was put into operation. It was not patented, and I do not know that it could be. I had a well too hard to work by man power; I hadn’t an engine, but there was engine power within my reach and I applied the present jerker system.”

Fairbank told the commission that prior to 1863, most wells in Oil Springs were powered by men and a spring pole. Although there were individual portable steam engines, they were not the norm.

“The jerker is universal now,” he said in 1890. “And it would be impossible to work upon the old system…With one engine now they work from half a dozen to eighty or ninety wells, with one boiler but often two engines.”

At Fairbank Oil, the Big Rig was built about 1905 and using coal, it powered an impressive 218 wells for a few decades before smaller additional rigs were built. The Big Rig building was large; 21meters by 9 meters (70 feet by 30 feet). Once electricity arrived in Oil Springs in 1918, its massive steam boilers were replaced by electric motors. Oil, in fact was among the first industries to be connected to the Ontario Hydro Electric power grid.

The move from small portable steam engines to the fixed and much more powerful rigs was progress. Portable steam engines were also be used for drilling beginning in the 1860s in Oil Springs.

It was a major loss to Fairbank Oil when the Big Rig burned in 1961 and was replaced by two smaller rigs, the East and West Rigs. The Big Rig’s boiler room was converted to a blacksmith shop.

These two enormous boilers are on view outside our blacksmith shop.

Because few today have ever seen a steam boiler, we have placed two boilers in front of the blacksmith shop. These particular boilers are huge; the diameter of each cylindrical boiler was 2 metres (6 feet) and measured 5 meters (16 feet) in length. They came from the old pear canning factory that operated in Petrolia during the 1950s.

Although steam power was eclipsed by electricity more than 100 years ago, steam power reigned for more than one-third of Fairbank Oil’s 160 years of operation.