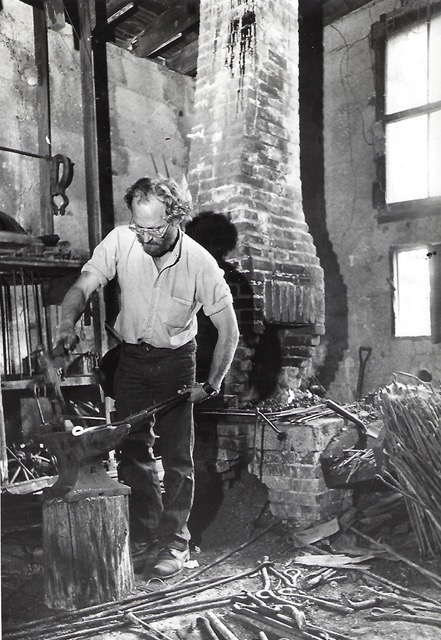

Charlie Fairbank hammering the loop hole he made in the iron rod to make a hanging iron for the jerker line.

To step into our blacksmith shop is to step back in time. While it’s known there were earlier versions of the blacksmith shop on the oil property, this one was created in one of our old powerhouses, known as The Big Rig.

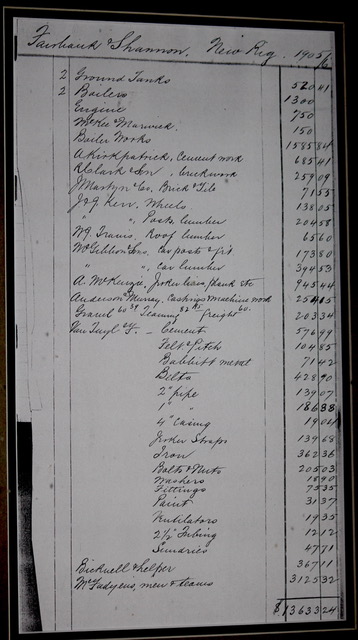

The Big Rig, also known as the Fairbank & Shannon Rig, was built in 1905 at a hefty sum of $13,366.24. We know this because a summary of the cost is framed on the wall.

Impressive, this rig powered up 200 wells. When it burned in 1961, it had to be replaced by not one, but two rigs, the East Rig and the West Rig. The Big Rig’s former boiler room was largely unscathed by the fire and converted into a blacksmith shop. The huge steam boilers were removed when electricity arrived here in 1918.The chimney and forge were not damaged by the flames but a wall just inside the shop is badly charred.

During the 1970s, Charlie Fairbank learned blacksmithing from the long-time employee Henry Wheeler. In the 1980s, Charlie refined his skills by taking a blacksmithing course outside of Detroit. For years, Charlie would go to the forge to make hanging irons for the jerker line system. With a looped end, they suspend on posts, allowing the jerker rods to swing back and forth, transferring power from the rig to the individual wells.

After tendonitis set in, he briefly replaced hanging irons with polypropylene rope. Authenticity was lost with the rope so he began making metal hangers once again but using the Hossfeld bender at the VanTuyl and Fairbank Hardware store in Petrolia. With the Hossfeld bender, a metal rod is inserted and by pushing hard, the bender creates the loop. With the store closing in 2019, the Hossfeld bender has been brought back to Fairbank Oil Fields to continue to be used in bending the metal in hanging irons. The Hossfeld bender was also used to bend the iron in making horseshoes.

Charlie Fairbank in the 1970s blacksmithing.

Photo by Sylvia Fairbank

The blacksmith shop is now used mainly for demonstrating how hanging irons were made for many years here. Anthracite coal is used for its ability to reach high heat.

In the oil field’s early days, a blacksmith designed tools to solve any oilman’s problem. Blacksmiths also supplied horseshoes and work horses were used here up until the 1950s.

The Big Rig was built in 1905 for $133,663.24 and powered an amazing 200 wells

The forge with anthracite coal used for fuel.

Photo by Al Hayward